Garbage trucks play a vital role in waste management systems, ensuring that our communities stay clean and hygienic. These heavy-duty vehicles are subjected to intense use and demanding operating conditions daily, which can take a toll on their performance and longevity. To ensure the smooth operation of your garbage truck fleet and minimize downtime, proper maintenance is crucial. In this article, we will explore essential tips for keeping your garbage truck fleet running smoothly.

- Regular Inspection and Preventive Maintenance Regular inspections are the cornerstone of effective garbage truck maintenance. Develop a comprehensive checklist that covers all critical components such as the engine, transmission, brakes, hydraulic system, and electrical system. Conduct these inspections at predetermined intervals and ensure that each truck in your fleet undergoes the same scrutiny. Identifying potential issues early on allows you to address them promptly and prevent more extensive damage.

- Fluids and Filters Regular fluid checks and changes are vital for the smooth functioning of your garbage trucks. Pay particular attention to engine oil, coolant, transmission fluid, and hydraulic fluid. Follow the manufacturer’s recommendations for the appropriate types and intervals for fluid changes. Additionally, regularly inspect and replace filters, including oil filters, air filters, and fuel filters. Clean fluids and filters help maintain optimal performance and protect your truck’s vital components.

- Tire Maintenance Garbage trucks endure significant weight and constant stop-and-go movements, which puts considerable stress on their tires. Check tire pressure regularly to ensure they are properly inflated. Over or under-inflated tires can lead to decreased fuel efficiency, poor handling, and increased tire wear. Inspect tires for signs of damage, such as cuts, bulges, or uneven wear, and replace them as necessary. Proper tire maintenance not only extends their lifespan but also contributes to better fuel economy and overall safety.

- Brake System The brake system of a garbage truck is crucial for the safety of both the vehicle and its surroundings. Regularly inspect the brake pads, rotors, and calipers for wear and tear. Ensure that the brake fluid is at the correct level and free of contaminants. Maintain accurate records of brake inspections and schedule regular brake system maintenance to avoid unexpected failures and accidents.

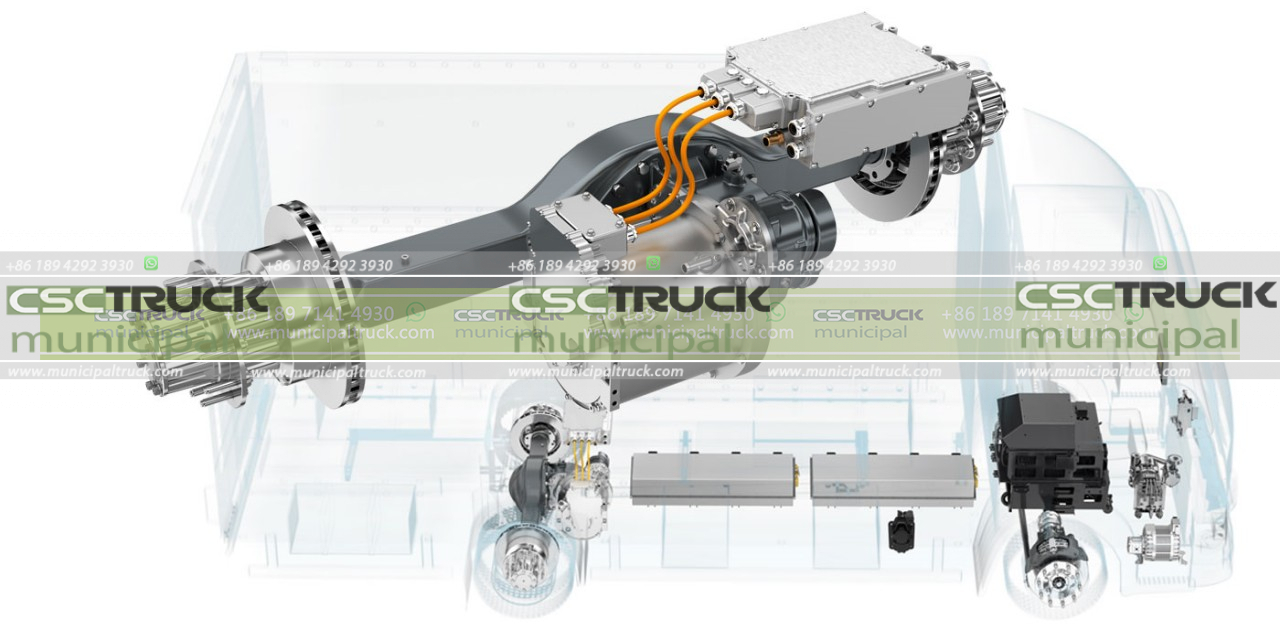

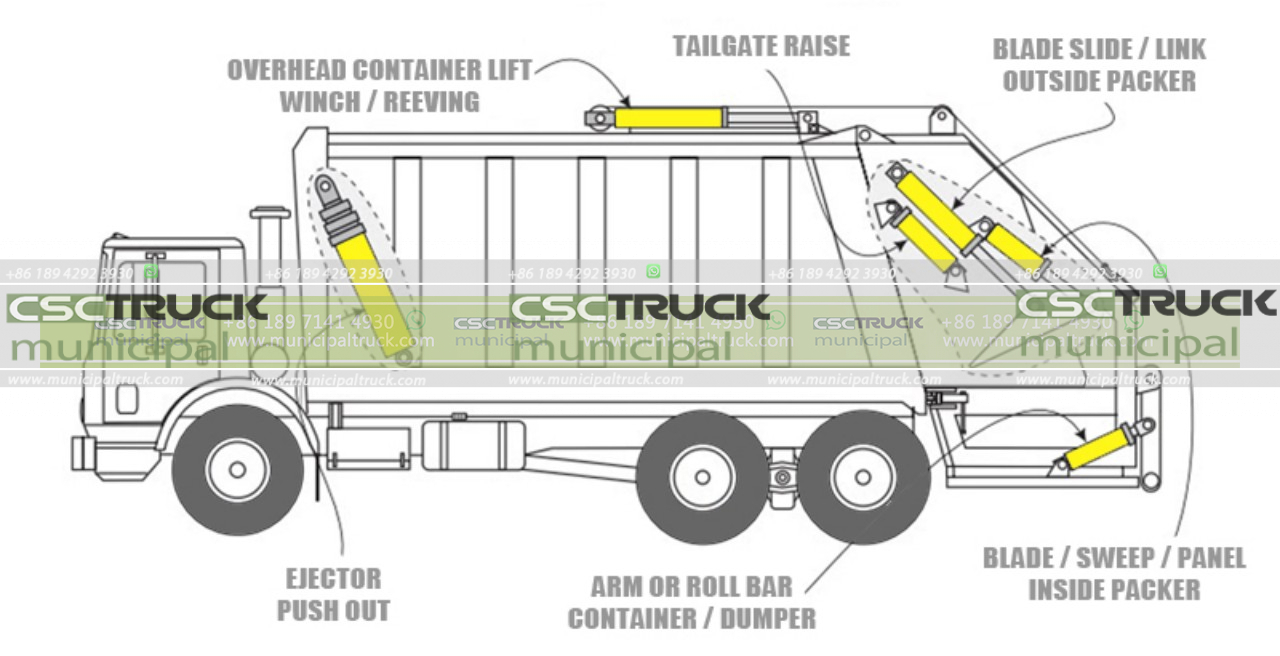

- Hydraulic System The hydraulic system of a garbage truck is responsible for lifting and emptying heavy waste containers. It is vital to keep this system in excellent condition to prevent breakdowns and delays in trash collection. Regularly inspect hydraulic hoses, cylinders, and valves for leaks, wear, and damage. Maintain the correct hydraulic fluid level and replace it as recommended by the manufacturer. Consider implementing a preventive maintenance program specifically for the hydraulic system to minimize downtime and ensure consistent performance.

- Electrical System The electrical system in a garbage truck controls various functions, including lights, sensors, and the compactor. Regularly inspect all wiring connections, fuses, and switches to ensure they are secure and in proper working order. Corrosion can be a common issue, so it is essential to address any signs of rust or damage promptly. Regularly test all electrical components to detect any issues early and prevent unexpected failures.

- Operator Training and Awareness Well-trained operators are key to maintaining the smooth operation of your garbage truck fleet. Provide comprehensive training to your drivers on vehicle operation, maintenance protocols, and safety procedures. Encourage operators to report any unusual noises, vibrations, or performance issues promptly. Foster a culture of awareness and accountability to ensure that potential problems are identified and addressed proactively.

- Documentation and Record-Keeping Maintaining detailed records of maintenance activities is crucial for tracking the health and performance of your garbage truck fleet. Keep track of inspections, repairs, parts replacements, and any other maintenance-related information. These records not only help in monitoring individual truck performance but also provide valuable insights for fleet management. Utilize digital platforms or maintenance management software to streamline the documentation process and ensure easy access to historical data when needed.

- Scheduled Servicing and Repairs In addition to regular inspections, schedule routine servicing and repairs for your garbage trucks. Adhere to the manufacturer’s recommended maintenance intervals and address any identified issues promptly. Follow a proactive approach rather than a reactive one to minimize unexpected breakdowns and costly repairs. Consider partnering with a reliable maintenance provider who specializes in garbage truck servicing to ensure expert care for your fleet.

- Cleanliness and Rust Prevention Garbage trucks are exposed to various corrosive elements, including waste materials, chemicals, and harsh weather conditions. Regularly clean the exterior and interior of your trucks to remove debris and prevent the accumulation of corrosive substances. Implement rust prevention measures such as applying protective coatings or sealants to vulnerable areas. A clean and rust-free truck not only enhances its aesthetics but also prolongs its lifespan and maintains its functionality.

- Communication and Feedback Establish effective channels of communication with your drivers and maintenance team. Encourage open dialogue and feedback regarding any maintenance issues or suggestions for improvement. Regularly review and analyze the feedback received to identify recurring problems and implement necessary changes. Engaging your team in the maintenance process creates a sense of ownership and promotes a collaborative approach to fleet management.

- Continuous Training and Education The field of vehicle maintenance is constantly evolving, and it is essential to stay updated with the latest industry practices and technologies. Invest in ongoing training and education programs for your maintenance staff to enhance their skills and knowledge. Stay informed about advancements in garbage truck technology and maintenance best practices to optimize the performance and efficiency of your fleet.

- Fleet Replacement Planning As garbage trucks age, their maintenance requirements and costs tend to increase. It is crucial to have a fleet replacement plan in place to ensure the timely retirement and replacement of older vehicles. Consider factors such as average lifespan, maintenance history, repair costs, and technological advancements when determining the optimal time for fleet replacement. A well-planned replacement strategy helps maintain a modern and efficient fleet while minimizing downtime and maximizing productivity.

In conclusion, proper maintenance is vital for keeping your garbage truck fleet running smoothly. Regular inspections, fluid and filter changes, tire maintenance, brake and hydraulic system care, electrical system checks, operator training, and documentation are all essential aspects of an effective maintenance program. By implementing these tips and adopting a proactive approach, you can minimize downtime, increase operational efficiency, and extend the lifespan of your garbage truck fleet. Remember, a well-maintained fleet ensures the uninterrupted flow of waste management services, contributing to cleaner and healthier communities.

In conclusion, proper maintenance is vital for keeping your garbage truck fleet running smoothly. Regular inspections, fluid and filter changes, tire maintenance, brake and hydraulic system care, electrical system checks, operator training, and documentation are all essential aspects of an effective maintenance program. By implementing these tips and adopting a proactive approach, you can minimize downtime, increase operational efficiency, and extend the lifespan of your garbage truck fleet. Remember, a well-maintained fleet ensures the uninterrupted flow of waste management services, contributing to cleaner and healthier communities.

Contact us for this municipal truck or similar trucks: [email protected] Call us or What's APP us: +86 189 4292 3930