The hydraulic system in a garbage truck is a key component responsible for many of the truck’s vital functions, including lifting, tipping, and compacting waste. Whether it’s a compactor garbage truck with its waste compression mechanisms or a side loader garbage truck used for residential waste collection, the hydraulic system ensures that these tasks are carried out efficiently and safely. Understanding how this system operates provides valuable insight into the inner workings of garbage trucks, highlighting their importance in the waste management industry. This guide will explain how the hydraulic system works in a garbage truck, the different functions it performs, and its role in enhancing operational efficiency.

1. Overview of the Hydraulic System in a Garbage Truck

At the core of most garbage trucks is the hydraulic system, a powerful force that makes it possible to carry out complex operations with relatively simple controls. The hydraulic system uses fluid to transfer force, allowing the garbage truck to perform tasks that would otherwise be impossible or inefficient with mechanical systems. This system’s strength lies in its ability to multiply force with minimal energy input, making it perfect for handling heavy loads of waste.

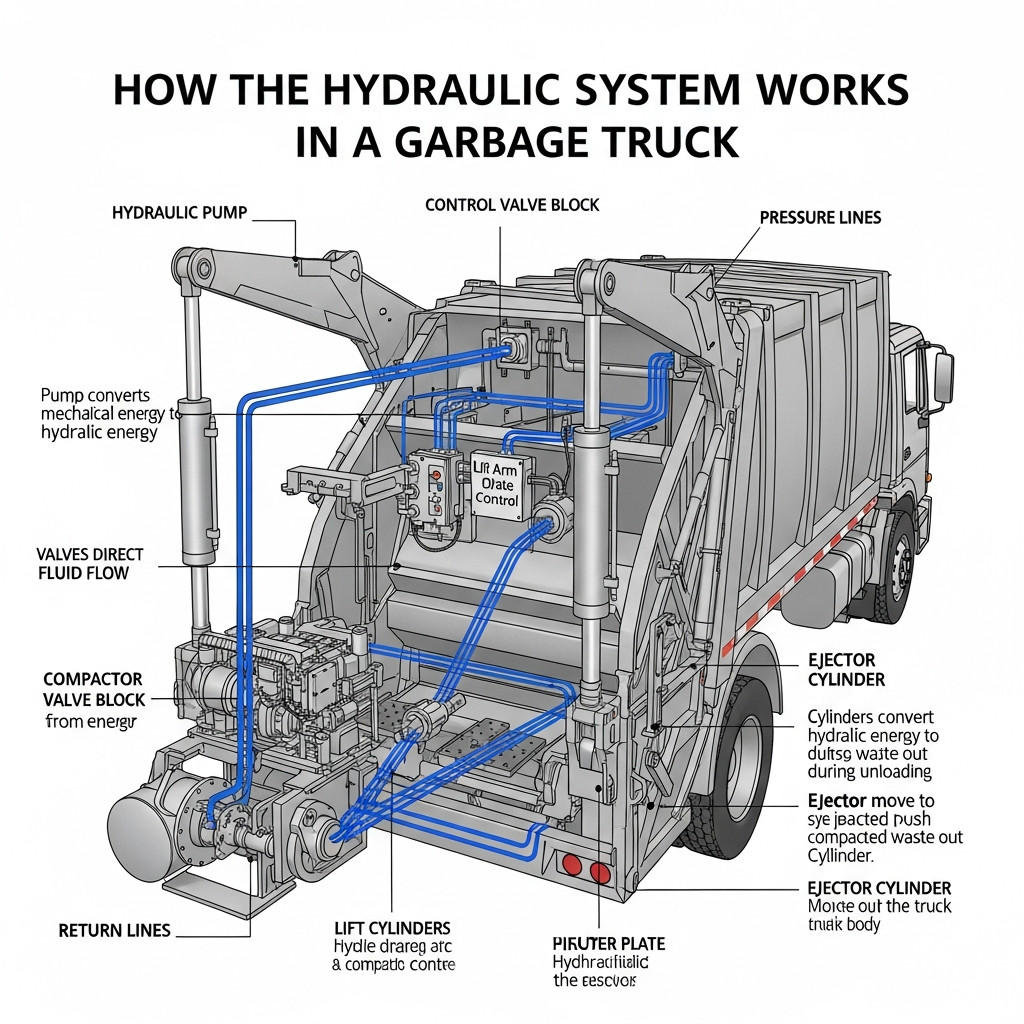

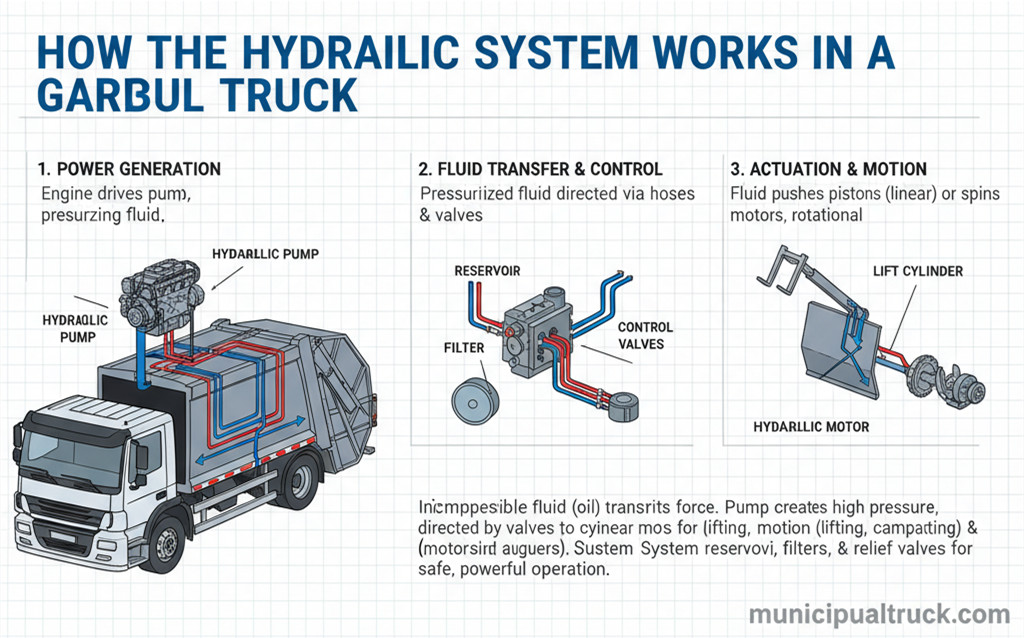

In a garbage truck, the hydraulic system consists of several key components: a hydraulic pump, reservoir, hoses, cylinders, and valves. The pump pressurizes hydraulic fluid, which is then directed to the cylinders via hoses and valves to perform the necessary functions. These components work together to lift and tilt the truck’s body, operate the compaction system, and manage the loading and unloading processes.

The Role of Pressure and Fluid Flow

Hydraulic systems rely on the principle of pressure to move fluid through the system. When the pump is activated, it generates high pressure, which forces fluid into the cylinders. The pressure applied to the fluid moves pistons within the cylinders, which in turn moves the truck’s lift arms, compacting plates, or other operational components. By controlling the flow and pressure, the system can easily move large, heavy loads.

2. Hydraulic System in a Compactor Garbage Truck

In a compactor garbage truck, the hydraulic system is primarily responsible for compacting waste in the truck’s container. Compaction allows the truck to carry more waste by reducing its volume, which is especially important for areas with high waste generation, such as urban centers or commercial districts. Without the hydraulic compaction system, garbage trucks would need to make multiple trips to dispose of the same amount of waste.

Compacting Waste with Hydraulic Force

The hydraulic system in a compactor garbage truck operates the compaction plate that pushes waste towards the back of the truck. This plate compresses the waste, making it denser and allowing the truck to carry a larger amount of waste without exceeding weight limits. The pressure from the hydraulic system is adjustable, allowing operators to control the level of compaction based on the type and volume of waste being collected.

Additionally, the hydraulic system helps lift the compactor garbage truck‘s rear or side containers. When the container is tipped to unload the waste, the hydraulic arms create enough force to lift even the heaviest loads, ensuring smooth and efficient unloading at the landfill or waste processing site.

Enhancing Efficiency and Reducing Costs

With the ability to compact waste using hydraulic pressure, compactor garbage trucks reduce the number of trips required for waste collection, saving fuel, time, and operational costs. The compacted waste also minimizes landfill overflow and improves waste management logistics, making it an essential feature in modern waste collection.

3. Hydraulic Functions in a Hook Loader Garbage Truck

A hook loader garbage truck uses a unique hydraulic system to load and unload waste containers, providing the flexibility to handle a variety of different waste materials. This system relies on the hydraulic hook lift mechanism, which is used to load, lift, and tip large waste containers (also known as bins or skips).

Loading and Unloading Containers with Hydraulic Power

The hydraulic system in a hook loader garbage truck is used to operate the hook lift system. The hook lift consists of a large arm and hook that can be extended and retracted to pick up and unload large containers. By applying hydraulic pressure, the arm is able to lift and tilt the container, allowing waste to be loaded or unloaded quickly and with minimal physical labor.

When loading containers, the hydraulic system lifts the container off the ground and hoists it onto the truck. During unloading, the system tilts the truck to allow the container to slide off, making it an efficient method for transporting various waste materials. The hydraulic system’s versatility makes the hook loader garbage truck ideal for use in different waste collection scenarios, from residential and commercial areas to construction sites.

Versatility and Adaptability

One of the major advantages of using a hydraulic system in a hook loader garbage truck is its adaptability. The system can easily handle containers of various sizes, providing flexibility for different types of waste collection. This adaptability is especially important for waste management companies that need to deal with a diverse range of materials and container sizes.

4. The Hydraulic System in a Self-Tipping Garbage Truck

A self-tipping garbage truck uses a hydraulic system to automate the unloading process, making it highly efficient for waste disposal. The hydraulic system in these trucks is responsible for lifting and tipping the truck’s body, allowing the waste to be unloaded without manual intervention.

Hydraulic Tipping Mechanism for Quick Unloading

The hydraulic system in a self-tipping garbage truck lifts the rear of the truck’s body, creating an incline for the waste to slide out. This tipping mechanism is especially useful in scenarios where rapid unloading is required, such as at waste transfer stations or landfills. The ability to unload waste quickly increases operational efficiency, as it reduces the amount of time spent at each collection site.

The hydraulic tipping system can also be precisely controlled, allowing operators to adjust the angle of the truck to ensure complete and efficient unloading. By leveraging hydraulic power, self-tipping garbage trucks reduce the manual labor needed during the unloading process and speed up overall waste management operations.

Reduced Labor and Increased Safety

The hydraulic system’s role in tipping the self-tipping garbage truck’s body also reduces the risk of accidents or injuries during the unloading process. Without the need for manual labor to empty the truck, there is less physical strain on workers, and the process is safer for everyone involved. This contributes to both the truck’s efficiency and the safety of waste management operations.

5. Maintenance of the Hydraulic System in a Garbage Truck

The hydraulic system in a garbage truck is a vital component that requires regular maintenance to function properly. While hydraulic systems are designed to be durable and reliable, wear and tear, fluid leaks, and component degradation can affect their performance over time. Proper care and maintenance of the hydraulic system can extend the lifespan of the truck and ensure optimal performance.

Regular Fluid Checks and Replacement

One of the most crucial maintenance tasks for the hydraulic system is checking and replacing the hydraulic fluid. Over time, hydraulic fluid can become contaminated with debris or degrade due to heat and pressure. This can lead to reduced efficiency or damage to the system’s components. Regular fluid checks and timely fluid replacement are necessary to keep the system running smoothly.

Inspecting Hoses and Seals

Hydraulic hoses and seals are prone to wear and tear, and it’s essential to inspect them regularly for signs of leaks or cracks. Any issues with hoses or seals can lead to a loss of hydraulic pressure, making the system less effective or causing complete failure. Timely replacement of worn parts ensures that the hydraulic system continues to function efficiently, allowing the garbage truck to perform its tasks without interruptions.

System Calibration and Component Checks

It’s also important to regularly check and calibrate the hydraulic system to ensure that it operates at optimal pressure levels. Any issues with the hydraulic pump, valves, or cylinders should be addressed promptly to prevent larger, more costly problems down the road. Keeping the hydraulic system in top condition ensures that the garbage truck operates at peak efficiency, improving both productivity and longevity.

The hydraulic system in a garbage truck is indispensable for performing key functions such as lifting, tipping, and compacting waste. Whether it’s a compactor garbage truck, a hook loader garbage truck, or a self-tipping garbage truck, the hydraulic system’s ability to apply controlled force makes waste collection more efficient and cost-effective. Understanding how this system operates allows waste management companies to maximize their operational potential, enhance safety, and ensure their trucks run smoothly for years to come.