Brief

FAW 16 Ton Sewer Septic Truck unit is mounted on a FAW J5M 4×2 Sleeper Cab. The tank volume of the sewage suction truck is 10,000L, made of Q235 carbon steel. Equipped with JUROP vacuum pump, flow capacity 5,300LPM. The sewer truck is with self-unloading function, and the back cover is hydraulically opened.

FAW 16 Ton Sewer Septic Truck adopts German craftsmanship, technology, and standards, combined with the actual working conditions, and uses electronically controlled single pump technology, which has good oil adaptability and excellent low-temperature start-up performance.

features

Chassis Truck

The open-front face design highlights the steady determination

Double Angle Door

Adapt to different spaces, up and down freely

Gearbox

Lightweight, aluminum housing, optimized gear ratio for low fuel consumption, low noise emission through optimized helical gears, interlock system to prevent mis-shifts.Input Torque: max 500N•m Speed Ratio Range: 7.94 Weight: 90 kg

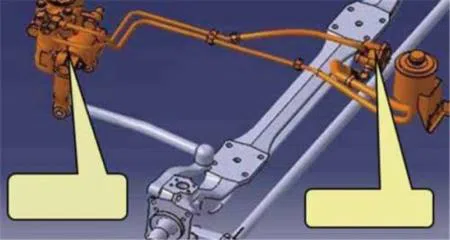

Driving pump flow increases can ensure the lightness of steering with heavy duty and the safety of steering at a high speed: return pipe diameter thickened, favorable to the system cooling, improve the stability of the system, extend the life of the components and the system.

LINEUP Different but professional model design satisfies different requirements for individuality.

Highlighted headlamps and all-LED taillights design shine all day long

Comfortable Car Space

Safe & Reliable

High-Quality Steel Reinforced Chassis

Efficient and Safe Steering System

Reinforced Chassis Capacity

Full riveted chassis, the frame is 0.5-2mm thicker than similar products Easy to refit: reasonable chassis layout, refit space Plate spring plate is durable: 300,000 km full load reliability test, durable.

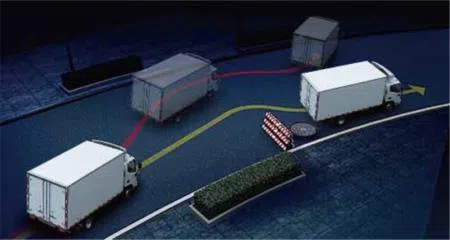

The blind spot mirror and front view mirror make everything visible to the eyes for a cool ride.

Surging Power Output

Integrated the world’s leading powertrain from CUMMINS/ISUZU engine and JMC/ZF transmission with exceptional performance, low weight, low operating costs, and reliability and durability.

Active and Passive Safety System

Versatility Diverse Cabins

3 cab models including day cab, sleeper cab, and crew cab. Various Dimension combinations: more than 10 combinations in dimensions of Length, Width, and Height. Different utilities: cargo or flatbed utility models as you need.

Body Unit

REAR – Tipping Tank

Double cylinders rear lifting

Vacuum Pump

FLOWSERVE SIHI LEMC90 Liquid ring vacuum pumps Suction volume flow: 20 to 200 m³/h

Overflowing

Air pump to safeguard pump from overflowing Sludge tank between the air pump and the tank.

Control

Four-way-cock manually controlled safety valve, manual controlled tank tipping, and rear lib opening.

Loading

3″ High level & 2.5″ Lower suction port with Ball Valve and Couplings

Discharge

Through a 4″ Ball valve with coupling mounted on the rear dish.

Rear Lib Skirting

Mounted under the rear lib to protect sewage spattering.

Installation

Tipping tank Subframe truck mounted

Accessories

– Full-length Hose platform on either side of the tank.

– Suction and delivery rubber hose 3″ x 4 m length fitted with couplings 2 nos.

– Mudguard and rubber mud flaps for the rear wheel.

– Rear bumper with anti-underrun protection.

– Level indicator sight glass

– Side marker lights

– Side crash guard

– Tank lifting hook

– Steel toolbox

– Steel water tank

– Fire extinguisher storage box

– Number plate

– Reflecting stickers as per traffic regulations

Rear Dish End

Manually openable side-hinged rear door and oil/fuel/sewage resistant rubber seal.

Safety Devices

– Primary Shutoff

– Pressure Relief Valve

– Vacuum Relief Valve

– Vacuum/Pressure Gauge

– Contents Indicator

– Oil /Gas /Water Separator

Painting

Sandblasted to Chinese Standard.

Internal coated epoxy lining.

External electrophoretic coating primer and top coated of high gloss finish PU paint in a single color ( customer choice)

specification

Cab Chassis Make/Model

AUMARK/FOTON

Wheel Drive

4×2 LHD

Approach /Departure Angle

23°/15°

Fuel Tank Capacity

120liers, steel

Max. Driving Speed

99 KM/h

Overall Size (L × W × H)

6000×2000×2450 (mm)

Front/Rear Overhang

1085/2550 mm

Wheelbase

3360 mm

Ground Clearance

210 mm

Front/Rear Track

1490/1425 mm

Gross Vehicle Weight(G.V.W)

8,000 kg

Payload Weight

4,070 kg

Tare Weight

3,780 kg

Front/Rear Axle Rating

2,200/5,000 kg

Cab Style

Day Cab

Cab Roof

Standard Roof with Streamline Dome

Construction

All steel construction

Instrument & Controls

All gauges and meters to be indicated in metric unit

Tiltable

Manual

Cab Model

AUMARK TX

Cab Width

L1800N

No. of Seats

1 driver plus two passengers

Driver Seats

Adjustable & separate from passengers’ seat

Equipment & Device

Manual A/C, Manual Open Doors & windows & rear view mirror/MP3/Knitted Ordinary Seat

Make/Model

FOTON-ISUZU/ BJ493ZLQV1

Max. Torque@Speed

280Nm@1900~2300r/min

Engine Type

4 Cylinders Vertical inline, water-cooled, 4-stroke, supercharged

Output Power@Speed

80kw@3600rpm

Displacement

2771ml

Emission Regulation

Class 3(EURO/CN Stage)

Type

Friction clutch, Disc diameter 380mm

Clutch Booster

Standard Equipped

Make/Model

JMC Gearbox/ JC5-28

Gear Numbers

5 speed forward, 1-speed reverse

Type

Manual shift control

Gear Ratio

Model/Make

Power Assisted

Hydraulic Power Assisted steering system

Position

Left Hand installed steering

Type

Ladder

Construction

Heavy duty construction and capable of withstanding the strain of rigorous on and off-road surface

Towing Device

The front towing device and rear trailer coupling be fitted on the chassis frame

Section Modulus

105/170/130×55×5mm

Bumper

Heavy duty front and rear steel bumpers are installed

Front Axle Model/Make

Rear Axle Model/Make

Rear Axle Ratio

6.142

Font Axle Type

Heavy duty “I – beam’’

Rear Axle Type

Heavy-duty, full–floating

Front

Heavy duty semi-elliptical front spring 3+1 no. leaf spring

Rear

Heavy duty semi-elliptical front spring 6+7 no. leaf spring

Wheels

6+1 nos.

Tires

7.00R16 Tube type

Rims

7.5-15 Steel Rim

Battery

Heavy duty, 2×12V, 180 Ah

Lighting

Headlights, parking lights, cabin interior lights, etc

Alternator Output

24V

Horns

electrical

Starter Motor Capacity

5.5kw

Warning Device

Audible and visible

Type

Pneumatically operated

Parking Brake

Mechanical spring-operated

Brake Control System

Load Sensing Proportional Valve

Service Brake

Dual system.Front and rear Drum type.

Engine Brake

Operating switch within driver’s reach

5000 Liters, 5 Cubic Meter, 1320 Gallon

Free Air Flow

333LPM to 3333 LPM

Max. Vertical Suction

≥8m

Tank Discharging Time

﹤4min

Tank Full loading Time

﹤5min

Reviews

There are no reviews yet.